The monthly news publication for aviation professionals.

The monthly news publication for aviation professionals.

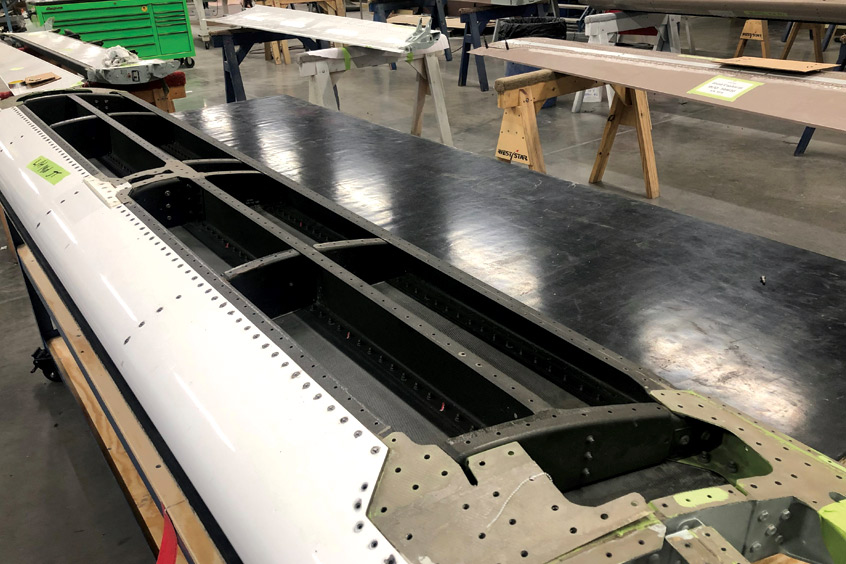

US business aviation MRO specialist West Star Aviation is supporting recent service bulletins regarding Global Express flap drainage and corrosion issues. The service bulletins are relevant to inspection and potential repairs on the inboard (I/B), middle and outboard (O/B) flap areas due to possible drainage and corrosion issues.

West Star has completed 25 I/B Global flap repairs and three sets of mid and O/Bs flaps to date. These service bulletins are not mandatory at this time but it is recommended that they be addressed at the next scheduled maintenance event. When scheduled in conjunction with the 120 or 240-month inspections, these service bulletins do not increase downtime. However, if scheduled during the 60-month or 180-month inspection, downtime may be increased slightly if full access is required due to corrosion inside the flaps. If the flap service bulletins are addressed independently of any other scheduled maintenance event, operators should expect downtimes up to six weeks.

“In addressing these service bulletin concerns on the Global flaps, we inspect for any damage that may have been caused due to poor drainage. If damage is found, the area is thoroughly cleaned, repaired and corrosion preventive is added to the area to reduce the possibility of recurrence,” states Brian Bauwens, director of Bombardier product development at West Star's St Louis Regional airport facility in Illinois. “Finally, additional drain holes are added to the area per manufacturer recommendations to complete the repair.”