The monthly news publication for aviation professionals.

The monthly news publication for aviation professionals.

Duncan Aviation has completed an industry-first STC for the Aviation Clean Air (ACA) ionisation system for a Global aircraft. This STC is available now for the Bombardier Global Express, Express XRS, 5000, 5500, and 6000.

The Duncan engineering and certification services team developed the STC to cover the installation of the safe and effective bipolar air ionisation units, and the team is also working on STCs for other makes and models, including a Challenger 300/350 slated for a late October completion.

“Most of us have always known there were dangerous viruses and bacteria in the world. We've all heard of the SARS and MERS viruses and drug-resistant bacteria, and now we can add COVID-19 to the list. Avoiding them mostly meant washing our hands often and thoroughly,” states Michael Kussatz, Duncan Aviation avionics regional sales manager in the eastern US. “We researched several products and found that the ACA ionisation system gives pilots and passengers a space where there is a very natural process that deactivates these pathogens, rendering them harmless, as we travel in comfort.”

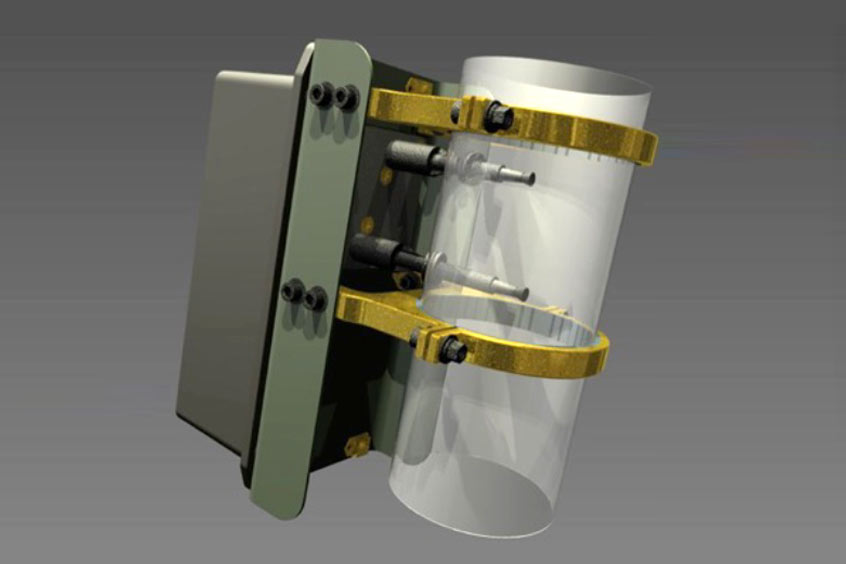

Designed to be installed in an aircraft's existing environmental control system, ACA is an air and surface purification system. The ACA system improves air quality throughout the aircraft and kills pathogens while removing allergens and unpleasant odours.

In May, testing conducted by independent lab Innovative BioAnalysis found the ACA ioniser effective at rendering harmless the novel coronavirus that causes COVID-19. The lab test showed that 99.4 per cent of the virus particles were inactivated within 30 minutes. The system has been tested and proven to kill the coronavirus that caused SARS (Severe Acute Respiratory Syndrome), as well.

The ionised hydrogen molecules also deactivate other viral, bacterial and fungal pathogens such as those that cause the common cold, flu (swine, avian, etc.), MRSA (methicillin-resistant Staphylococcus aureus), C. diff (clostridium difficile), E. coli (Escherichia coli), pneumonia, polio and mould.

In addition to pathogens, the ACA component neutralises potentially harmful gasses caused by fuel emissions, other volatile organic compounds, and offensive odours caused by cooking or cleaning, cigarette and cigar smoke, stagnant air and lavatories. Pet odours are also neutralised. The system will also reduce the static electricity in aircraft that is caused by the low relative humidity of the cabin air.

Because installation can typically be completed in less than two weeks, Duncan Aviation can install the ACA air ioniser as a stand-alone event or part of a scheduled-maintenance event at its three main facilities in Battle Creek, Michigan; Lincoln, Nebraska; or Provo, Utah or at its 28 satellite shops or workaway stations around the country.