Archer Aviation

Aircraft

Atlanta (Covington Municipal) Airport

BAN's World Gazetteer

California The monthly news publication for aviation professionals.

The monthly news publication for aviation professionals.

eVTOL developer Archer Aviation has signed up Garmin to supply the G3000 integrated flight deck for its Midnight aircraft. The Garmin G3000 is a compact and lightweight system that offers both an extensive certification pedigree and the configurability needed for Archer to bring its aircraft to market. The large format displays and intuitive controls will provide pilots with the situational awareness needed to operate Midnight, and the extensive reach of Garmin avionics will make the Midnight aircraft familiar to a large swath of pilots.

Part of Archer's commercialisation strategy is to focus its in-house development on only the key enabling technologies that cannot be sourced from the existing aerospace supply base. The Garmin relationship further advances Archer's approach of establishing strategic relationships for supply of components already being used on certified aircraft today. Archer now has more than 64 per cent of its suppliers for Midnight's bill-of-materials selected.

“By aligning Archer's product sourcing needs with the experience and capabilities of well-established leaders in the aviation industry, we can help reduce our certification risk, as well as development timelines and costs,” says CEO Adam Goldstein. “We're excited to be adding Garmin to our growing base of world-class suppliers as we pave the way towards commercialisation.”

“It is an honour to be selected and trusted by Archer, and we are confident the G3000 will help it to provide advanced and efficient air taxi services for years to come,” adds executive vice president and managing director, aviation Phil Straub.

Garmin maintains an exceptional reputation for delivering high-quality avionic technologies to general aviation, business aviation, rotorcraft, advanced air mobility, government and defence, and commercial air carrier customers. Its extensive experience in the aviation space and demonstrated ability to reliably source flight deck avionic systems was a significant factor in Archer's decision to enter into this relationship.

Molicel is to manufacture and supply the battery cells for the Midnight aircraft, which is being built to perform back-to-back short distance flights of about 20 miles with approximately 10 minute charging cycles in between. Batteries are an important consideration in achieving Midnight's desired payload, range and charging time. The ability to operate eVTOL aircraft in dense, urban environments requires reliable battery cells that can deliver high power, low impedance and fast charging capabilities.

Molicel’s first Gigafactory in Taiwan is scheduled to ramp up production in 2023. The facility will have the capacity to produce 1.8 gigawatt-hours (GWh) of battery capacity annually. Molicel's high-performance cells also offer a significant cycle life when utilised in Archer's battery pack and, as a result, reduce the long-term operating cost for its production aircraft. Partnering with a battery supplier that can reliably manufacture cells at scale, allows Archer to reduce its certification risk, as well as its development timelines and costs.

“Molicel understands that safety and reliability are paramount but that we still must ensure we are living up to our shared values of social responsibility and sustainability,” says Goldstein.

“We hope to see the great impact that Midnight will introduce to the marketplace technology-wise, safety-wise and most importantly, to prove a profitable business model that a new technology can offer while being sustainable and responsible for the environment,” says president Casey Shiue.

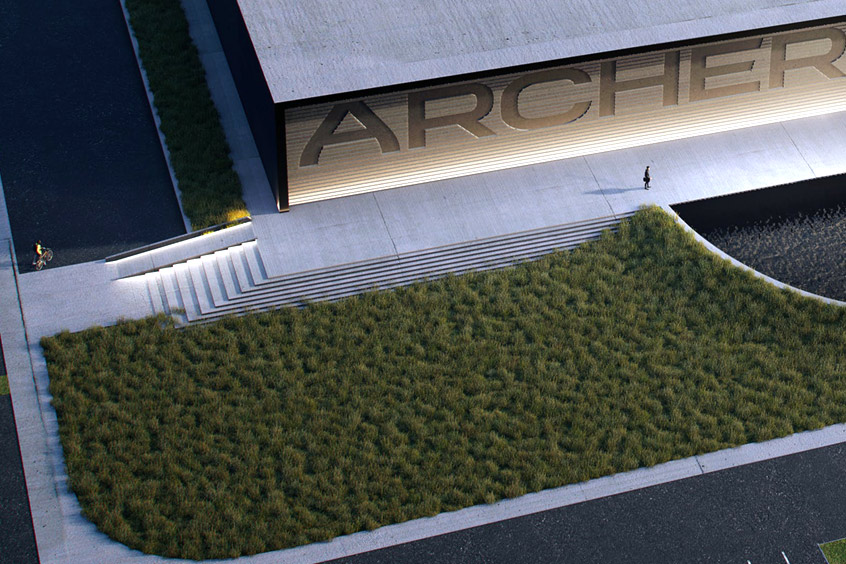

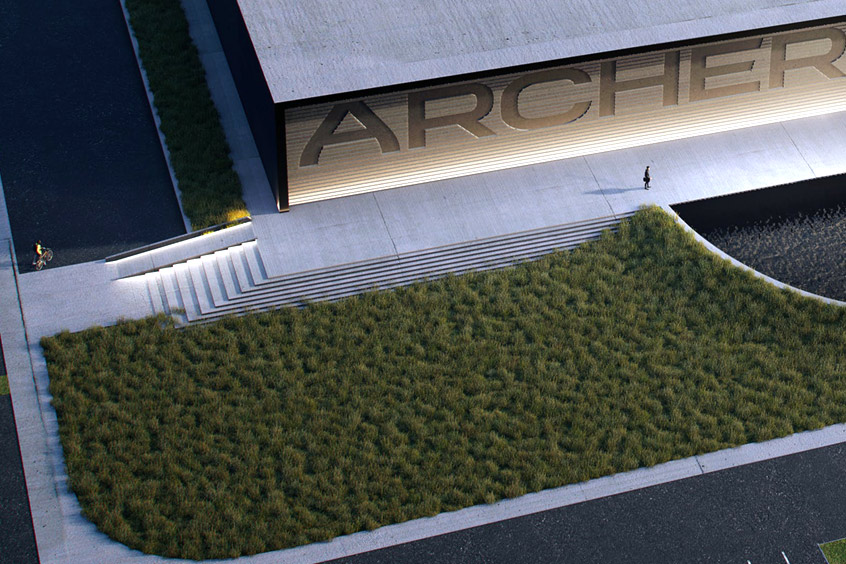

Archer has taken the decision to locate its eVTOL manufacturing facility in Covington, Georgia at a site adjacent to the Covington Municipal airport. A 350,000 sq ft facility will initially be built on a 96 acre site capable of producing up to 650 aircraft per year, and Archer expects to create more than 1,000 jobs over the long term. Construction is expected to be completed in the first half of 2024 with initial production expected to begin in the second half of 2024. The facility will be capable of being expanded by an additional 550,000 sq ft, which is estimated to support production of up to 2,300 aircraft per year.

In selecting the location for its first manufacturing facility, Archer completed a comprehensive survey of potential sites across the US. Key considerations included the availability of talent in the local labour market, utility availability, ability to conduct seamless flight test operations, construction costs and logistics. Archer will receive an incentive package, which includes land conveyance, tax incentives and Georgia REBA grant. As it looks to build its local community-focused relationships in Georgia, the company anticipates that financing for the project will be provided by Synovus, the largest bank headquartered in the state.

“After many months of discussion and evaluation, we're excited to select Georgia as the location for our manufacturing facility,” says Goldstein. “The US has long led the world in aerospace technology, and Georgia has played a vital role in that industry. Our eVTOL technology can transform how urban and rural communities live and commute and this factory can create pathways to highly skilled manufacturing jobs and other ladders of social and economic opportunity. I am grateful to Governor Kemp along with Bob Kosek, Sara Gershon, Serra Hall, Frank Turner and their teams, as well as all my colleagues at Archer as we work together to pioneer these innovative aviation technologies.”

Governor Brian P Kemp adds: “Georgia has made nurturing innovation a priority as we work with businesses to define the future. Our established leadership in the aerospace industry was essential to landing Archer Aviation in Newton County. We are thrilled to welcome Archer to the state of Georgia, where it can take advantage of our signature workforce training programme Quick Start to help fill, in the long term, over 1,000 jobs in Covington.”

Home to more than 800 aerospace companies, Georgia maintains a robust aerospace education pipeline, with a dozen high schools that offer training in the field, five technical colleges with aviation programmes, and several universities offering degrees in aerospace engineering. A strategic arm of the Georgia Department of Economic Development, the Georgia Center of Innovation for Aerospace, has been cultivating an ecosystem of opportunities for innovative companies like Archer for more than 10 years.